01

Background

Tesla, Inc. is an American automotive and energy company based in Palo Alto, California. The company specializes in electric car manufacturing and solar panel manufacturing. It operates multiple production and assembly plants, notably Gigafactory 1 near Reno, Nevada, and its main vehicle manufacturing facility at Tesla Factory in Fremont, California. Their lineup consists of the Model S, Model X, and Model 3 vehicles, with an exciting product roadmap ahead including the Model Y, Semi, and Roadster. After 10 years in the market, Tesla ranked as the world's best-selling plug-in passenger car manufacturer in 2018, both as a brand and by automotive group. [1]

I had the opportunity to join a small team of engineers at Tesla Headquarters in Palo Alto, California to develop Tesla's next generation architecture for the upcoming Model Y. The six of us on the New Technologies and Architectures team were challenged with making decisions for the communication architecture and power distribution to minimize costs, improve performance, and increase automation.

The Tesla Factory, Tesla's primary vehicle manufacturing facility in Fremont, California

The Tesla Factory, Tesla's primary vehicle manufacturing facility in Fremont, California

02

Approach

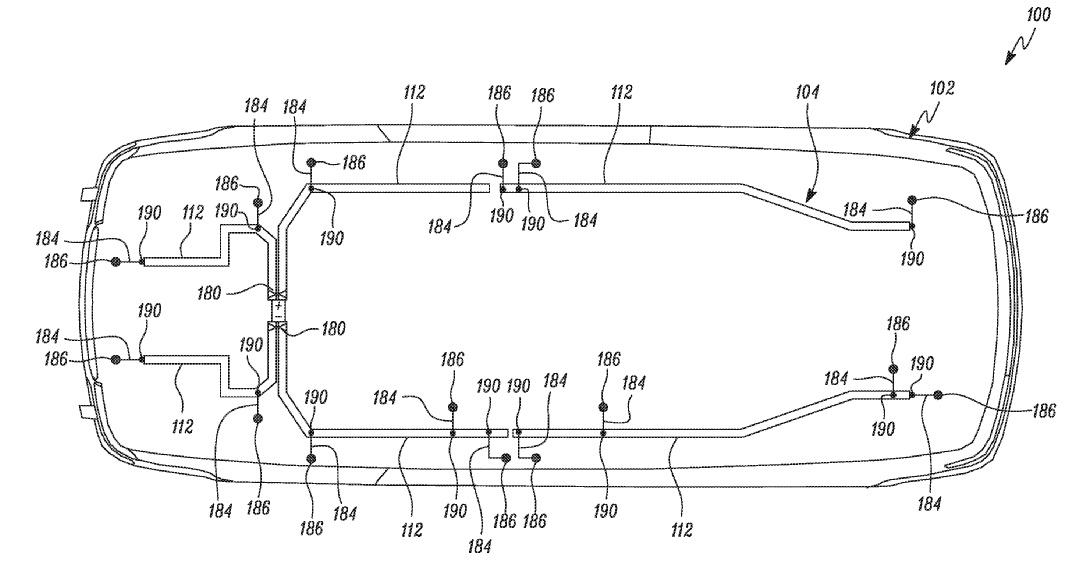

Traditional car wiring for vehicles are piecemeal solutions. Typically, there are different wiring harnesses that connect each different electrical component to a central battery or power source. Each component receives power, but requires multiple wiring harnesses for communication and signals. The total length of the wire may be many miles within a single vehicle. These wiring harnesses typically consist of multiple round conductors that are not rigid. Round conductors are not optimal for transmitting current and the lack of rigidity of traditional wiring harnesses requires assembly into the vehicle using human hands, which can be a slow process. Further, connecting each component to the central battery is not optimized on an automobile level. Hence, there is a need for wires and a wiring-system architecture that overcomes the aforementioned drawbacks.

Top view of an automobile showing a body and a wiring system for connecting a plurality of devices to a backbone.

Top view of an automobile showing a body and a wiring system for connecting a plurality of devices to a backbone.

03

Reception

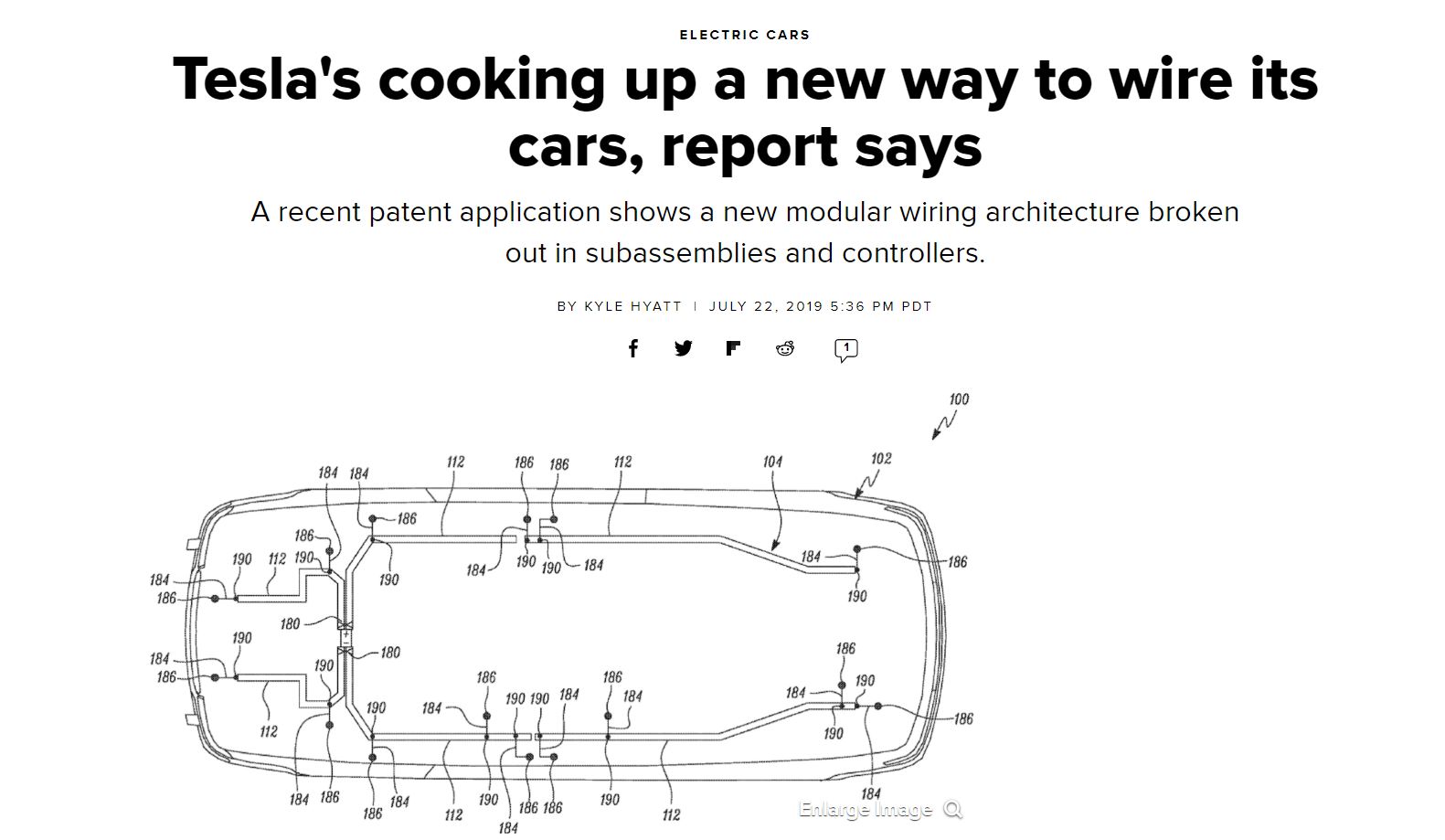

Since the patent was published, news outlets such as CNET, InsideEVs, and Electrek have described our work as "revolutionary":

"Tesla reveals revolutionary new wiring architecture to help robots build upcoming cars like Model Y"

"Tesla's cooking up a new way to wire its cars, report says"

"New Tesla Model Y Wiring System Is Revolutionary"

05

Patent

If you'd like to read our patent for information, feel free to click the link below.

PatentScope Link